Use this information to install a microprocessor and heat sink.

Note: This procedure should be performed only by trained service

technicians.

Before you install a microprocessor and heat

sink, complete the following steps:

- Read Safety and Installation guidelines.

- If the compute node is installed in a chassis, remove it (see Removing a compute node from a chassis for instructions).

- Carefully lay the compute node on a flat, static-protective surface, orienting the compute node with the bezel pointing toward you.

The following notes describe the type of microprocessor

that the compute node supports and other information that you must

consider when you install a microprocessor:

- This component can be installed as an optional device or as a CRU. The installation procedure is the same for the optional device and the CRU.

- The optional microprocessors that Lenovo supports are limited by the capacity and capability of the compute node. Any microprocessors that you install must have the same specifications as the microprocessors that came with the compute node.

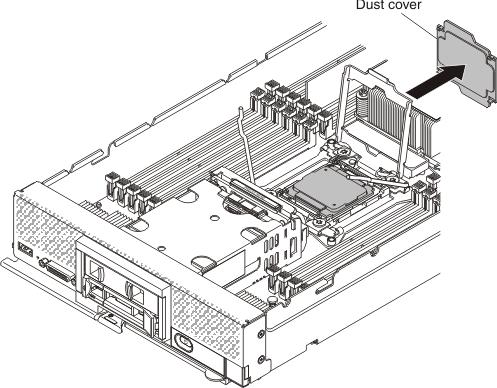

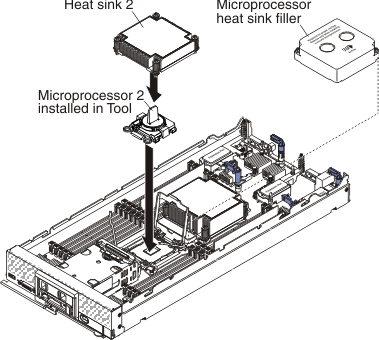

- Each microprocessor socket must always contain a heat-sink filler or a microprocessor and heat sink. If the compute node has only one microprocessor, it must be installed in microprocessor socket 1.

- If you are installing a second microprocessor, make sure that the microprocessors are identical.

- Before you install a new microprocessor, download and install the most current level of UEFI code (see Updating firmware and device drivers).

- When you install a second microprocessor, you might have to install additional memory or redistribute memory across the DIMM connectors (see Installing a DIMM).

- Installing microprocessor 2 enables DIMM connectors 13 through 24 and the expansion connector (see System-board connectors). Microprocessor 2 is also required by some optional devices, such as PCIe hard disk drives, that can be installed in the compute node (see documentation that comes with the optional device for additional information and requirements).

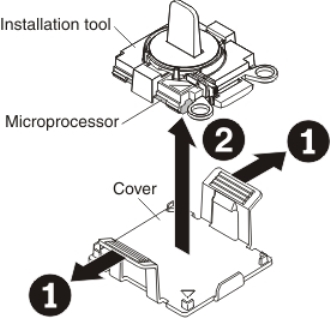

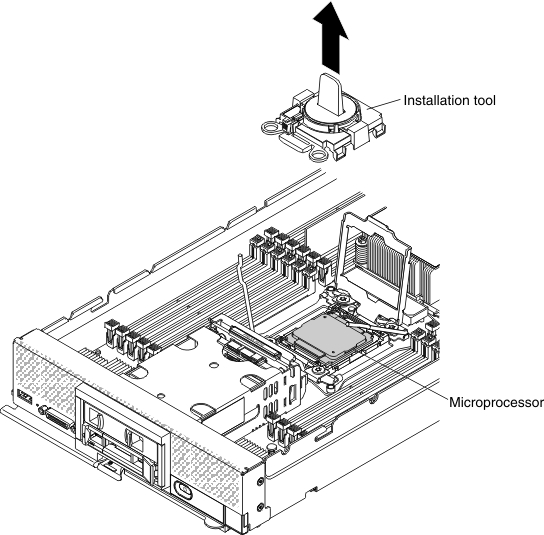

- The microprocessor installation tool might become worn after several uses. Make sure that the tool can hold the microprocessor securely if you are reusing an existing microprocessor installation tool. Do not return the tool with other parts that you are returning.

- If you are installing a second microprocessor, the microprocessor option kit comes with a microprocessor installation tool that you must use when you install a microprocessor. The microprocessor installation tool comes with the replacement microprocessor installed on it and a cover over the microprocessor.

- If you are replacing a defective microprocessor, the CRU kit comes with one installation tool with the replacement microprocessor installed on it and a cover over the microprocessor, and one empty installation tool without a cover.

- If you are replacing a defective microprocessor, you must obtain

the following for use during the replacement procedure (see Parts listing, Types 9532 and 2951).

- Alcohol wipes

- Thermal grease

Attention:

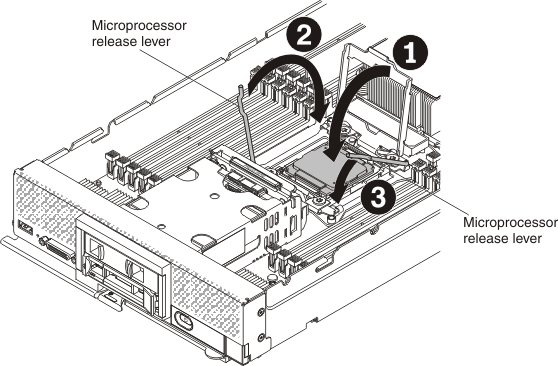

- Remove and install only one microprocessor at a time. When removing or installing a microprocessor, protect the other microprocessor socket with a microprocessor heat sink filler.

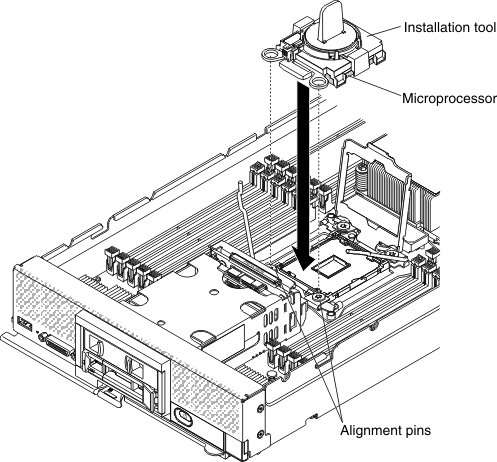

- Always use the microprocessor installation tool to remove or install a microprocessor. Failure to use the microprocessor installation tool can damage the microprocessor sockets on the system board. Any damage to the microprocessor sockets might require replacing the system board.

- Different microprocessor types might require a different type of heat sink. To maintain adequate cooling, make sure that you install the heat sink type specified for your microprocessor.

- Thermal grease can stay functional on the heat sink for two years. When installing a new heat sink, make sure to check the manufacturing date to ensure the thermal grease is still functioning. If the date is over two years ago, replace the thermal grease to avoid seating issues.

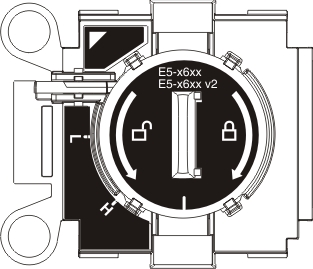

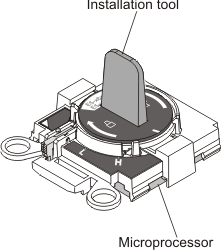

Note: Be sure to use the installation

tool that comes with your microprocessor. The installation tool has

two settings for installing two different sizes of microprocessors.

The settings that are marked on the tool are

Lfor smaller low core microprocessors, and

Hfor larger high core microprocessors. The tool automatically adjusts during use to the correct setting for your microprocessor.

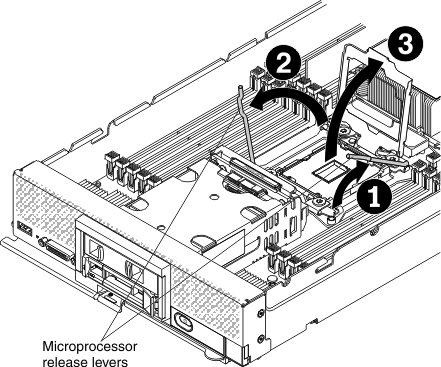

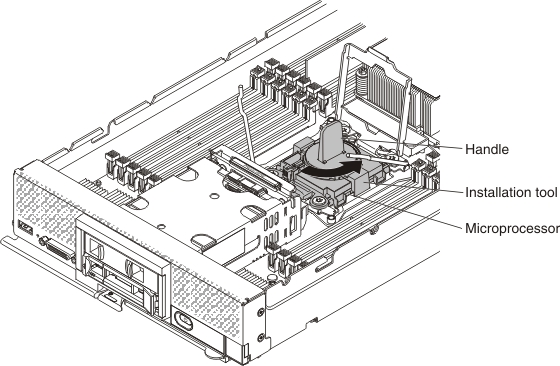

To install a microprocessor and heat sink, complete the following steps.

After you install a microprocessor and heat sink, complete

the following steps:

- Install the cover (see Installing the compute node cover).

- Install the compute node in a Lenovo Flex System chassis (see Installing a compute node in a chassis for instructions).